When it comes to planning your budget, you may be overlooking one area that could dramatically impact your bottom line—asset and inventory management. There’s a lot of hidden costs associated with lost, obsolete, expired, and damaged items, including the capital used to initial purchase the inventory, finance and interest charges, insurance, and handling costs.

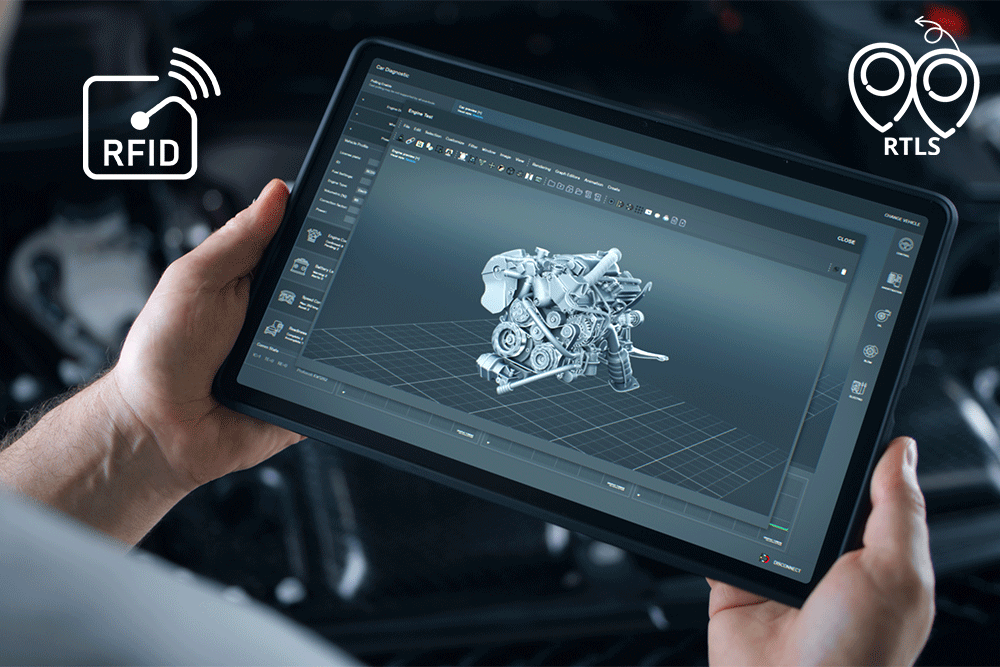

As prices for everything continue to rise and leaders are asked to do more with less, a growing number of companies are exploring real-time location services (RTLS) to mitigate the risks of misplaced or lost goods. But what if you could take that a step further and generate income?

With TRACE Sensors RTLS, you can shift your bottom line to cut your losses and increase your revenue-generating potential. Here are 9 ways you can turn your asset management liabilities into income opportunities.

-

Missing items

Missing itemsInventory management can be tricky since there are many ways items can go missing. Workers can ship the wrong item by mistake, for example, or leave an asset somewhere and simply forget about it. Missed scans for items removed from inventory will also add up over time, compounding the problem of out-of-date records. There’s a lot to be gained by maintaining a current picture of your inventory and its cash value. TRACE Sensors RTLS provides you with a picture of all your tagged assets and inventory in real time mitigating the risk of missing items.

-

Replacing items

This is never as simple as plugging in the dollar value of a lost item. From delays in waiting for new products to be manufactured and shipped to purchase order requisitions, approvals, third-party buyers, and other congestible cogs, replacing items is rarely as easy as swiping a credit card. Consider, if you have to replace 100 units of a product at $50 a pop. You theoretically losing $5,000 in revenue. But what if the anticipated profit margin was 30% or 40% or 50%? You’ve lost the opportunity to earn that profit. With RTLS, you can not only find missing assets faster, but you can also hinder theft within your facility by clearly identifying who and what was where and when.

-

Damaged/expired items

Raw materials like steel and food items have expiration dates. Without proper asset tracking, using RTLS, first in and first out doesn’t come into play. Even with your best efforts at assigning and managing inventory dates, if you don’t have a clear view into your stockroom and factory floor—at the asset or palette level—you’re really just guessing. And with the ever-increasing value of these materials, you could be losing more than you think. TRACE Sensors enables you to view asset history in your facility and provides you with the data you need to enhance inventory management and workflows.

-

Labor costs

Labor costs represent one of the biggest reasons to improve asset tracking. Every time an employee has to stop what they’re doing to look for the right tool or find a particular asset, you’re wasting money that can add up to paying for a lot of nothing. Manual inventory management is inefficient, costly, and just plain dumb. One company calculated that they spent 47% of their time “just looking for the right tools.” At that rate, you could substantially reduce labor costs, utilizing RTLS, and use those resources to fuel innovation.

-

Unplanned downtime

In manufacturing settings, unplanned downtime can be as expensive as $260K per hour. This typically means halting production, shipping, and other key services that bring in cash for the organization. Something as simple as a misplaced work order can lead to unintended downtime. It’s difficult to pursue money-making work when your operations are stalled. The data provided by TRACE Sensors, enables you to streamline workflows to ensure you’re not only driving efficiency, you’re also able to mitigate downtime.

-

Dead/obsolete inventory

For many well-run companies, anywhere from 20-30% of inventory is dead or obsolete. The total cost of holding inventory can represent a shocking 25-30% more than the inventory’s unit cost value. In addition, having your cash tied-up in inventory-related expenses has an opportunity cost, which can translate to as much as 15% or more. With RTLS, you can get ahead of this loss, and even turn it around to benefit your profit margins.

-

Real estate

The expense to own, rent, or maintain a physical space is another element to evaluate. Occupying or keeping your workplace operable is expensive, whether or not the whole space is in use. This can be a huge overhead expense and really add up with temperature control, security, and insurance. Having an in-depth understanding of your inventory with TRACE Sensors, enables you to use your real estate more wisely, and dramatically cut spending.

-

Your reputation

We’ve all become impatient with the supply chain, and if you could deliver on expectations more often than not, your customers will thank you for it in spades. As we’ve discussed, RTLS can help you drive efficiency throughout your part of the supply chain, and even make up for let downs further up the channel. This is not only saving you money, but a particular niche to drive greater revenue.

-

Improvement success

We’ve looked at all the things that RTLS for asset and inventory tracking can fix, so let’s look at how it can generate revenue by improving work processes. If each of the points above were to save you 10% that’s 80% you can add to your budget. What could that get you? More customers, increased innovative efforts, enhanced stakeholder trust and satisfaction, and greater confidence of your customers, employees, and shareholders. Priceless. TRACE Sensors enables you to:

- Quickly and accurately search and locate industrial assets throughout your facility

- Track workflows and adjust them to drive efficiency

- Increase workforce coordination and productivity

- Monitor deviations from expected processes and perform root-cause analysis

- Automate control and auditing of work done by third parties

- Reduce associated workforce costs and liabilities

Expand your possibilities without expanding your budget with TRACE Sensors RTLS. Give us 15 minutes of your time, and we can show you how TRACE Sensors can turn your budget liabilities into revenue-generating opportunities.

Expand your possibilities without expanding your budget with TRACE Sensors RTLS. Give us 15 minutes of your time, and we can show you how TRACE Sensors can turn your budget liabilities into revenue-generating opportunities.