The steel industry isn’t one that is immediately known for embracing digital transformation. However, in a highly competitive market, manufacturers realize it’s necessary to streamline operations in order to not only save time but save money and their reputations with customers.

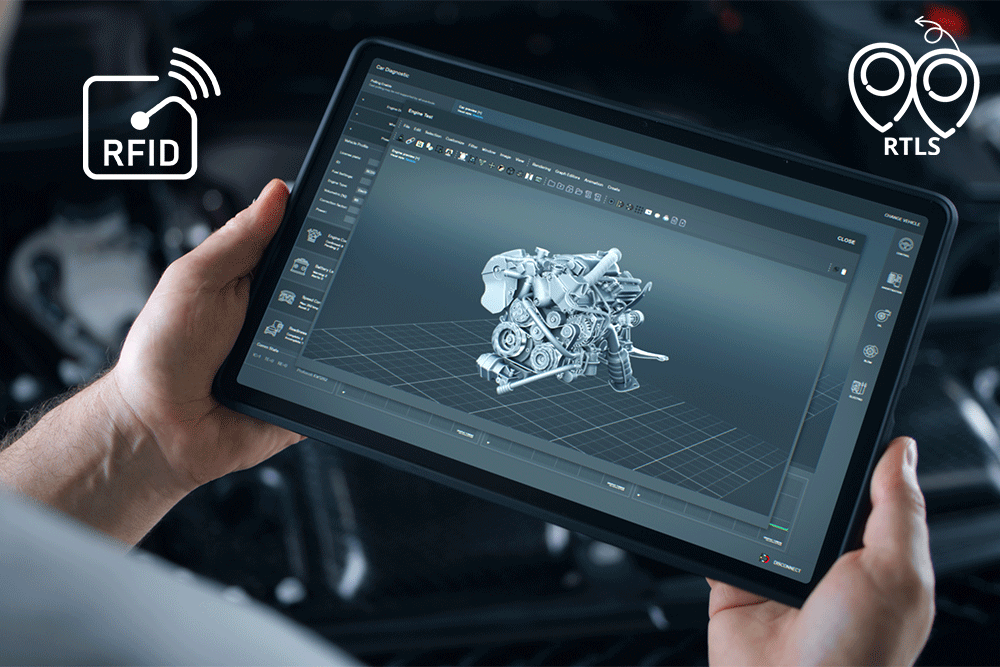

Not all asset and inventory management solutions are the same. Many rely on radio frequency identification (RFID) which is not optimal for environments comprised of a lot of reflective materials—like a steel manufacturing facility. Let’s take a look at what’s getting in the way of optimizing your asset management goals and how i-Virtualize’s TRACE Sensors Real-Time Location Services can help.

Gaining Insights

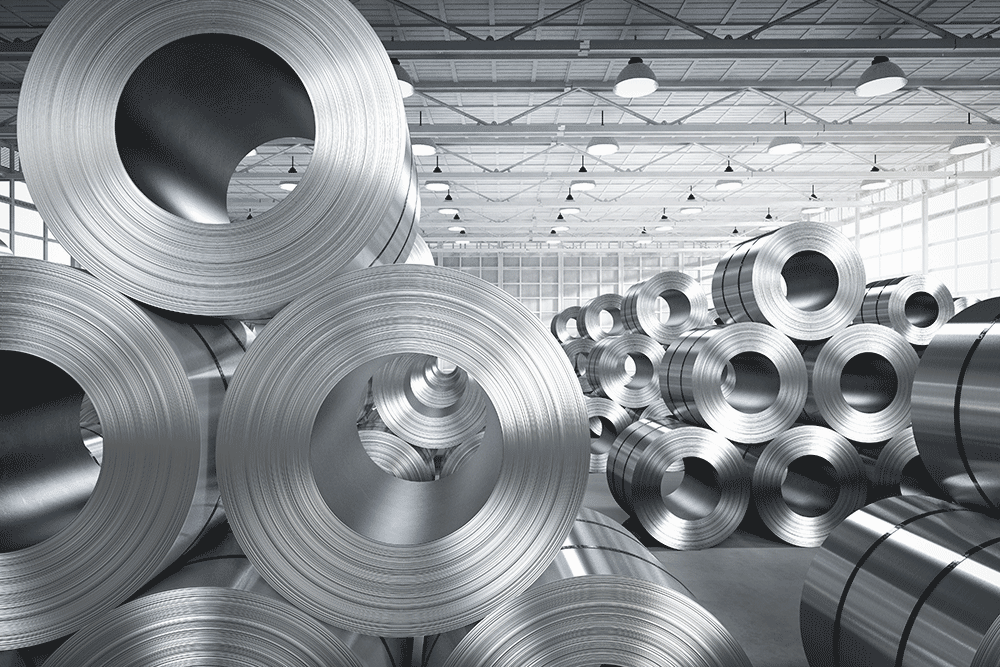

Blind ordering and shipping hinders your ability to see the entire supply chain. With a shortage of raw materials, the more exact you can be during the ordering process can stabilize your profit margins. Knowing exactly what is going out so you can order enough to fill that demand without being stuck with excess is essential for long-term growth.

Tagging and automatically tracking inventory from the mill to the customer, enables steelmakers to see with new eyes, establishing a level of continuity that was unavailable previously. Otherwise, you’re relying on employees to manually scan bar codes along the product’s journey. This has proven to be a highly ineffective since scanning the codes as the product arrives at each stage of the process is often overlooked.

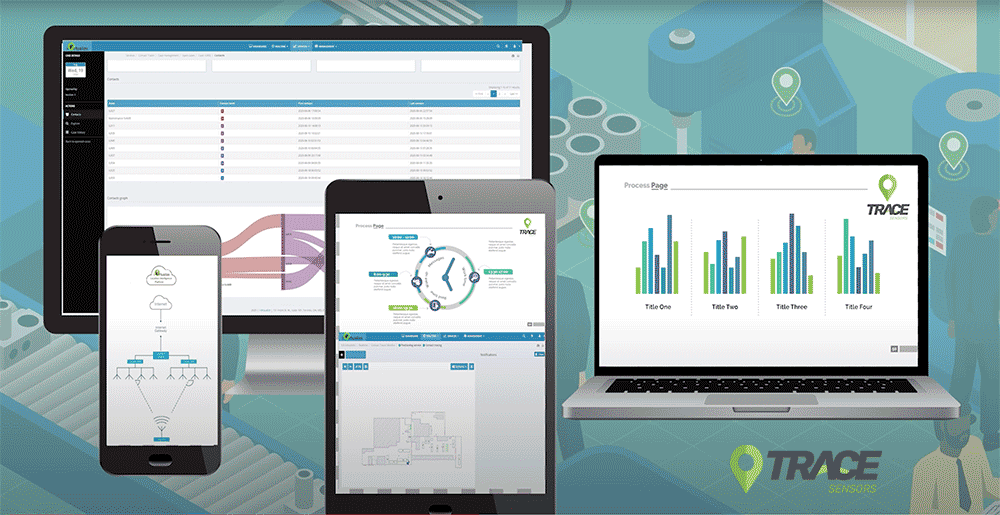

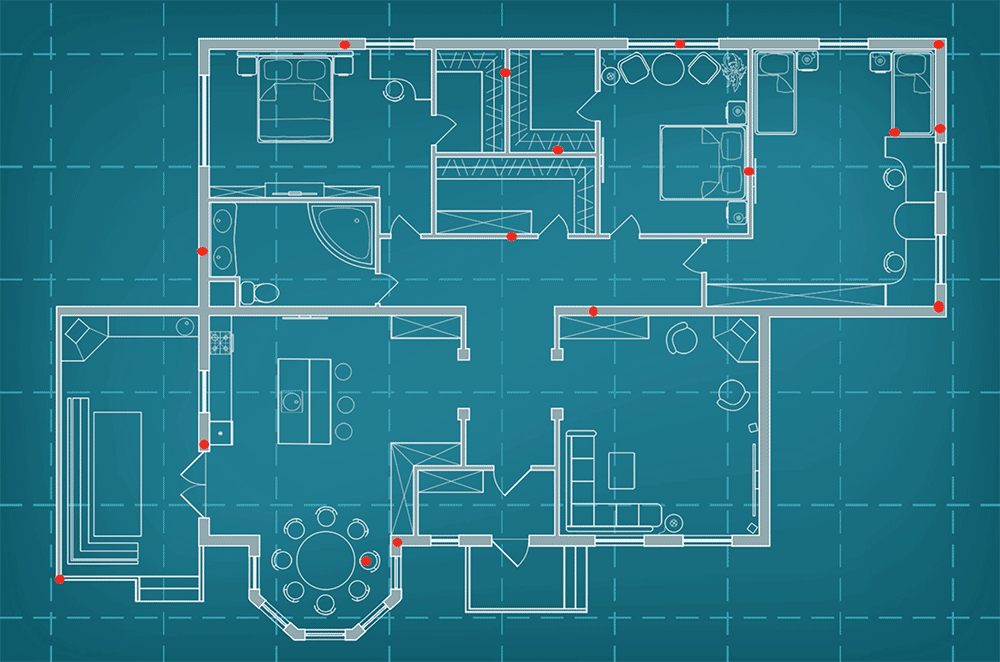

TRACE Sensors RTLS utilizes a digital twin of your environment with ceiling locators and tags on inventory and assets to make workflows more dynamic and reliable. By automatically seeing where materials are in the process, you can track their location throughout your facility without your employees having to manually scan codes.

For many manufacturers, the process of locating materials often includes employees climbing ladders and looking for tiny numbers or codes that identify each piece. This is an extremely time-consuming process. When materials can’t be found quickly, the decision is often to just order more. Either way this process is inefficient, wasteful and can cut into your profits.

Utilizing RTLS to find materials quickly means products get out the door faster, you reduce overtime, hire fewer people, and you ship more finished products per day, saving tens of thousands of dollars a day.

RTLS is the next step to digitalizing the supply chain and automating the entire customer journey. By tagging customers’ orders manufacturers now see when their customers received the order and possibly automate ordering when supply levels are low. This tightens the supply chain and enhances your ability to increase productivity and streamline your workflows.

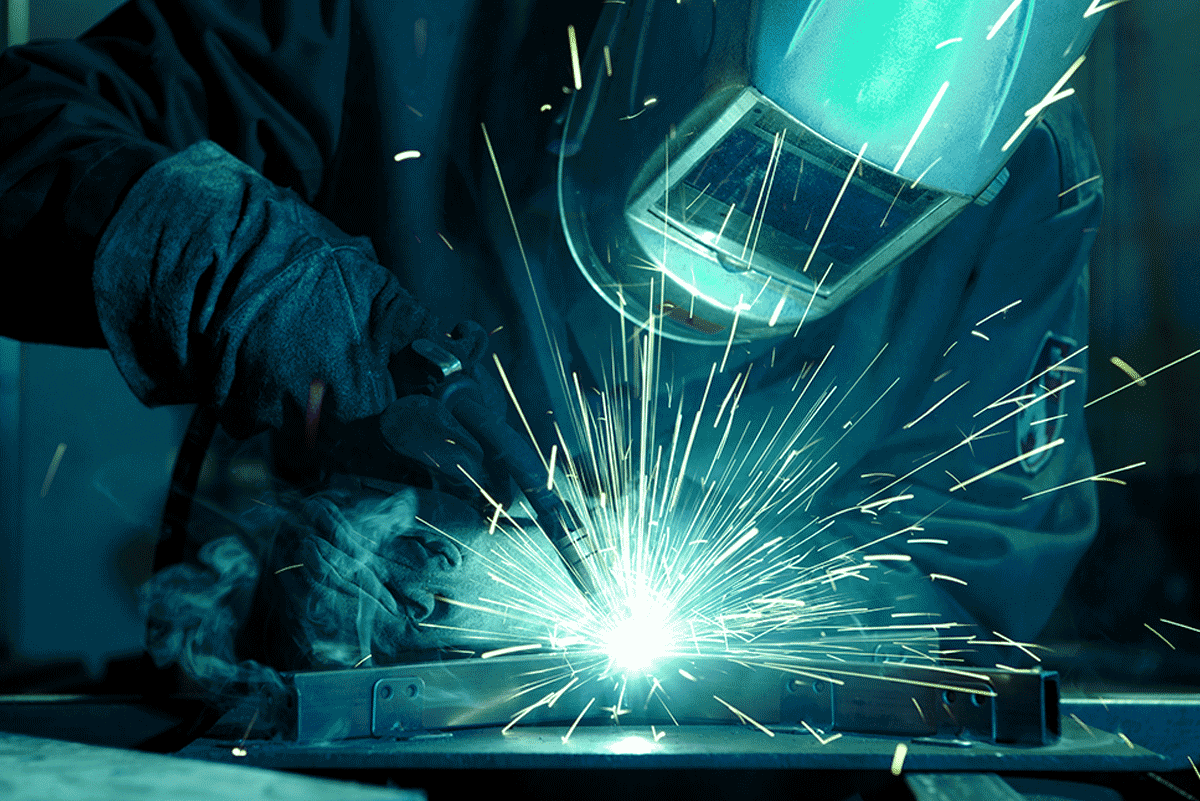

Cutting Losses

Combine the cost of damaged materials and the fluctuating prices of raw steel, and it’s easy to find yourself getting buried in overhead costs. Since steel in its raw state is highly perishable, the need to put that into play as soon as possible is often key to inhibiting the loss of material and profits.

Most steel manufacturers follow a first in, first out (FIFO) inventory management method. The goal is to give priority to the output of products that have been stored the longest and can expire. However, without accurate real-time location identification, many companies miss the mark. Every error can cut into your bottom line and with the price of steel only rising, it could negatively impact your margins or your sustainability.

The TRACE Sensors interactive dashboard clearly identifies not only where materials are located, but you can see how long they’ve been sitting on the shelf to determine which to use first.

What makes TRACE Sensors unique is that we’ve developed a method to tune the reception sensitivity of each locator to help the system deliver better results in the challenging metal environment. Instead of giving a location estimate of a zone, TRACE Sensors uses pinpoint accuracy of less than 2 metres, enabling employees to quickly find what they need and get back to work. TRACE Sensors enables businesses to work smarter and more economically instead of wasting time and valuable resources.

Engage and Integrate with Your Customers

Digital transformation in the steel industry has opened the door for manufacturers to take advantage of more opportunities in filling the needs of their customers and in recruiting new talent.

Structural steel fabrication is a competitive industry, and if you can’t meet your customers’ deadlines, you lose out on future opportunities. It’s not uncommon for products to be delivered to the customer’s loading dock, but the customer is unable to find them. When your customer can’t locate the product you sent, the common solution is to ensure fulfillment, so you duplicate the order again and hope to figure out what happened later. This isn’t only highly disruptive to fabrication, rush orders cause errors, and put other customers’ orders on the back burner, increasing overtime and eroding the partnership.

By tagging customer products, you ensure the products left your facility, and know the exact departure time, so customers can better identify where these products are in their logistical journey. Monitoring the location of products to your customers also eliminates wasted materials which could be sitting out in the weather quickly oxidizing and becoming useless.

As an important thread of the global economy, the steel industry is always on the lookout for new talent. Antiquated ways of doing things aren’t going to inspire a new generation of workers. The steel industry must embrace digitalization to increase its viability in the job market and entice technologically savvy job seekers to want to be a part of this industry.

Empowering Manufacturing

Combining industry-leading innovative technologies—state-of-the-art locators from Quuppa, cutting-edge software and analytics from ThinkIn, and Gartner Magic Quadrant storage solutions from NetApp—with i-Virtualize’s team of experienced, problem-solving engineers, TRACE Sensors Real-time Location Services raises the bar for automated asset and inventory management.

Because metal manufacturing is a unique environment, the standard asset location functionalities of RFID fall short of delivering the necessary accuracy steelmakers demand. TRACE Sensors utilizes Bluetooth technology along with highly trained IT specialists to design an environment where the signals from tag to locators is not interrupted by the feedback associated with bouncing off of metal. Our experienced team know the right number and correct positioning of the locators to optimize RTLS efficiency.

With TRACE Sensors, you can:

- Improve operational efficiency, enabling your company to negotiate better delivery rates

- Tell the story of workflows, revenue, and profits using data analytics, instead of estimating and assuming

- Do more by bringing disparate silos of data together in a way that helps business leaders make more impactful decisions

Find out how i-Virtualize can help strengthen your steel business with TRACE Sensors.